Coil Mate

The L.C. Miller Company is the originator of quick-change coil devices used extensively in the induction heating operations.

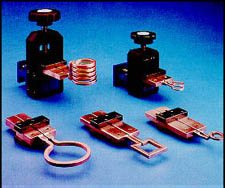

Coil-Mate models are miniature devices for power levels up to 10kw. The salient features are:

1. Robust, aesthetically designed single piece insulated housing.

2. Two built-in automatic water valves which operate when changing from one coil to another. When a coil is removed by unscrewing the top knob, the water is automatically turned off. When another coil is inserted in place the water again flows through the coil. Because of the very high currents, ample water flow through the coil is necessary. This is a significant time saving feature, which obviates the need for external valves and eliminates the burning - up of expensive coils in the advent that these valves are not turned on.

3. Low induction, low contact resistance is achieved by micro-finished, silver plated contact surfaces. Characteristically, solid - state systems operate at low voltages, thus for a given power it produces a correspondingly higher current. Conversely, vacuum tube systems which operate at much higher voltages, require much less current and the need for very low contact resistance is less critical.

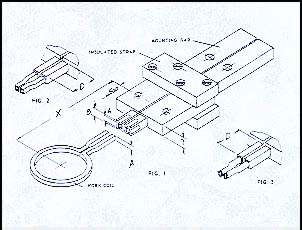

In many operations, where various size parts are processed, different coils are employed to accommodate each size. The coils are soft-solder into the appropriate terminal bars.

Flux Concentrators: Increased coil efficiency can be achieved by using flux concentrators; materials of high magnetic permeability, when applied selectively to the coil, will improve efficiency from 20 - 50 percent. Heating times can be improved often with a reduction in power.